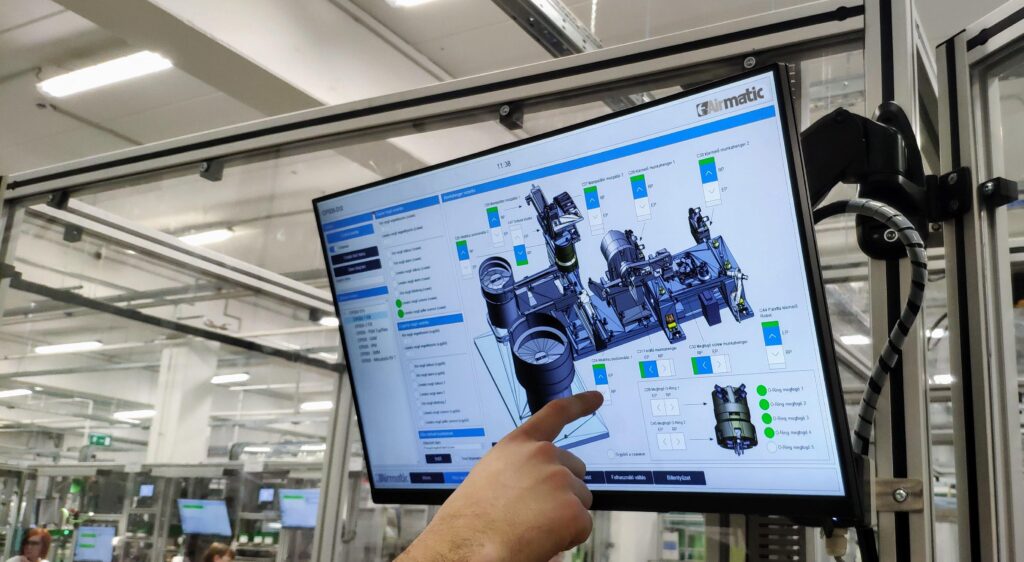

Conforming to our customers requirements, we have built a fully automatic conveyor and palette based assembly line, which includes a manual assembly workstation with automatic palette receiving and forwarding. The assembly line’s main purpose is to assemble, adjust and test a gas-valve part, after which a robot places the finished and tested part in a plastic crate for storage.

The main parts of the assembly line are the following:

-Bosch rexroth conveyor system and custom, RFID equipped palettes;

-5 custom designed and built workstations which are responsible for the assembly and testing tasks;

-Adjusting workstation with PID controlled FESTO stepper motor;

-Mitsubishi Electric RV Series 6 axis robot;

-National Instrument Industrial controller based line controlling with custom HMI;

-Line server for data save, import, parameter and user handling;