Building a High-Performance Automatic Press and Assembly Machine: Overcoming Challenges and Achieving Success

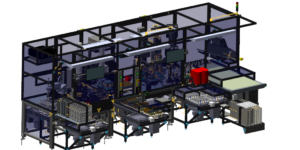

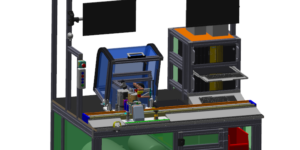

Over the past year, we worked on an outstanding project that involved building a three-robot, rotary table automatic press and assembly machine. The design and construction of the machine was …